- ABB

- GE

- NI

- EPRO

- METSO

- weida

- STS

- VMIC

- Hima

- KEBA

- B&R

- FANUC

- YASKAWA

- B&R

- KOLLMORGEN

- Other

- RELIANCE ELECTRIC

- Westinghouse

- ICS TRIPLEX

- Schneider

- MOORE

- YOKOGAWA

- ACQUISITIONLOGIC

- OKUMA

- SELECTRON

- SYNRAD

- PROSOFT

- Motorola

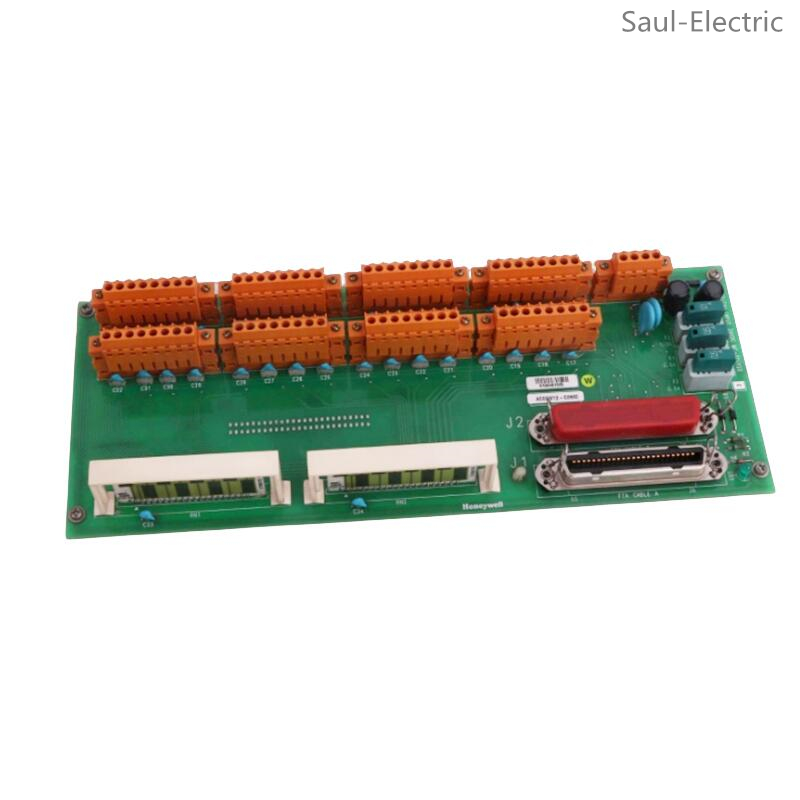

- Honeywell

- Bently

- Allen-Bradley

- Rockwell Ics Triplex

- Woodward

- Other Parts

- Triconex

- Foxboro

- Emerson

0102030405

ABB PP820 3BSE042243R2 Touch Screen Panel DCS

HONG KONG SAUL ELECTRICAL LIMITED

E-mail:sales2@xrjdcs.com

whatsapp :+86-15359273791

Tel:+86-15359273791

ABB PP820 3BSE042243R2 Touch Screen Panel DCS

ABB PP820 3BSE042243R2 Touch Screen Panel DCS

ABB PP820 3BSE042243R2 Touch Screen Panel DCS

1. A-B Rockwell: 1746, 1747, 1756, 1771, 1784, 1785 series PLC and 2711 series touch screen;

2. Foxboro Foxboro: I / a DCS series, such as fbm237 and fbm242;

3. Trnex Invensys: TRN DCS series, such as 30083501e;

4. Westinghouse: ovation DCS series, such as 1c31110g03, 5x00105g03;

Schneider Schneider: 140plc series, such as 140cpu67160;

6. GE Fanuc FANUC: ic693, ic697, ic698 and other series;

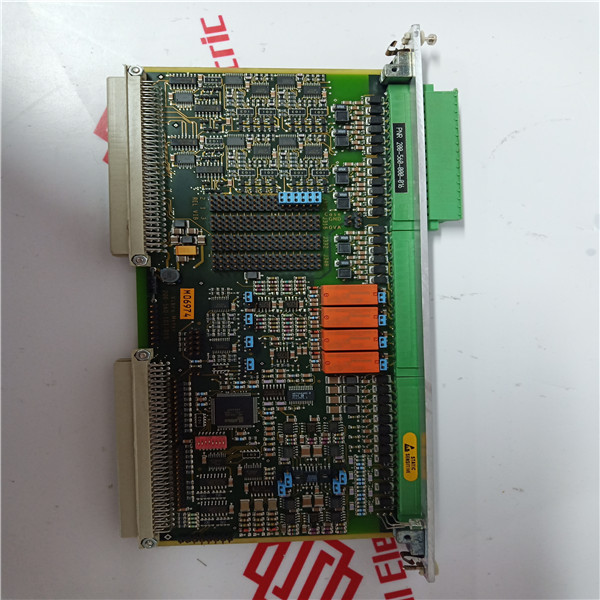

7. Siemens: S5 series, such as 6es5100-8ma02; CNC control system: etc.

Rexroth indrama Rexroth: servo drive, servo control, etc., such as dkc03.3-040-7-fw.

9. ABB: robot control system dsqc series, such as dsqc235a; Bailey INFI90 series, such as immfp01.

10. Honeywell: tdc2000, TDC3000 and other shutdown DCS spare parts, such as 51400762-100.

11. Bently Nevada Bentley: 3500 series, 3300 series, 33180 head proximitor, 33780 head proximitor, 330130 head cable, etc

12. Yokogawa Yokogawa: CS3000 system, CPU module, power supply, input / output module, card and other spare parts, such as mri-234 * B

With the wide application of DCS in thermal power plants, its dominant position in the safe and stable operation of units is becoming more and more prominent. Due to the reliability of software and hardware of DCS equipment, the perfection and rationality of control logic, the maintenance and overhaul level of thermal personnel and many other factors, unit false tripping events still occur from time to time. Therefore, effective technical management and correct overhaul and maintenance to maintain the stable and reliable operation of thermal power unit DCs has increasingly become the focus of daily management and maintenance of thermal workers. Therefore, combined with the above case analysis, the author puts forward some preventive measures to improve the reliability of the control system for reference in maintenance:

● implement the whole process management for DCS equipment and maintenance, find defects as soon as possible and deal with them in time. Improve the DCS self diagnosis and fault alarm functions. The real-time monitoring of DCS operation status should not only monitor the status of the main controller, but also monitor the status of the main controller network.

● formulate a reasonable regular maintenance system, specify the contents, methods and cycles of inspection and maintenance in detail, analyze the inspection results and take targeted preventive measures. Since the trial implementation of this system, Zhenhai Power Plant has effectively controlled the occurrence of DCS faults.

● formulate DCS emergency plan and typical fault handling scheme to prevent DCS fault caused by improper maintenance.

● select high-quality spare parts, such as cooling fan and DP plug of main controller, and replace vulnerable parts regularly.

● remotely monitor the ambient temperature of the electronic room, access DCS display, and master the change of the ambient temperature of the electronic room in real time. The electronic room with central air conditioner shall also pay attention to the control of humidity. If necessary, an independent air conditioner or dehumidification device shall be installed.

● check the appearance of module circuit board during maintenance, which can play a good preventive effect.